Concrete Plant Precast Technology

Hardwall Concrete Faced ICFs. ThermalSert Insulation Insert. HOW TO BUILD. Frost Walls & Stem Walls. ICF Door & Window Openings. Manufacturer Construction and Engineering Statement. BuildBlock Insulating Concrete Forms (ICFs) are one of the strongest and most energy-efficient building materials available today.

Rectangular 4 Inch Foam Concrete Block at best price in Bengaluru ID 20316632312

The built-in anti-lift technology, locking all blocks down by concrete pressure on it. This eliminates the need to tie or lock down each row, making your installation faster. Design Flexibility SuperForm ICFs are designed with maximum design freedom with a 1″ repeating cut lines.

manual moulds for foam concrete blocks/manual moulds for foam concrete interlock blocks, View

LiteBar Built to Be Stronger, Lighter and Rust Free Learn More Advancing Building Technology Now, advanced Insulated Concrete Forms (ICFs) from LiteForm, the world leader in ICF construction technology, gives you superior alternatives to build sustainable, environmentally conscious concrete structures.

Molds for the production of foamed concrete foam blocks series Robus Buy on

Insulated concrete formwork, commonly known as ICF, is a construction method used in home building that utilizes styrofoam foundation forms to create a strong and well-insulated structure. It's an alternative to traditional wood-frame housing.

Foam Construction Cinder Blocks Becker's School Supplies

Foam concrete A cylinder of foam concrete. Foam concrete, also known as Lightweight Cellular Concrete (LCC) and Low Density Cellular Concrete (LDCC), and by other names, is defined as a cement -based slurry, with a minimum of 20% (per volume) foam entrained into the plastic mortar. [1]

Aerated concrete, foam сoncrete block making machine ARK005 YouTube

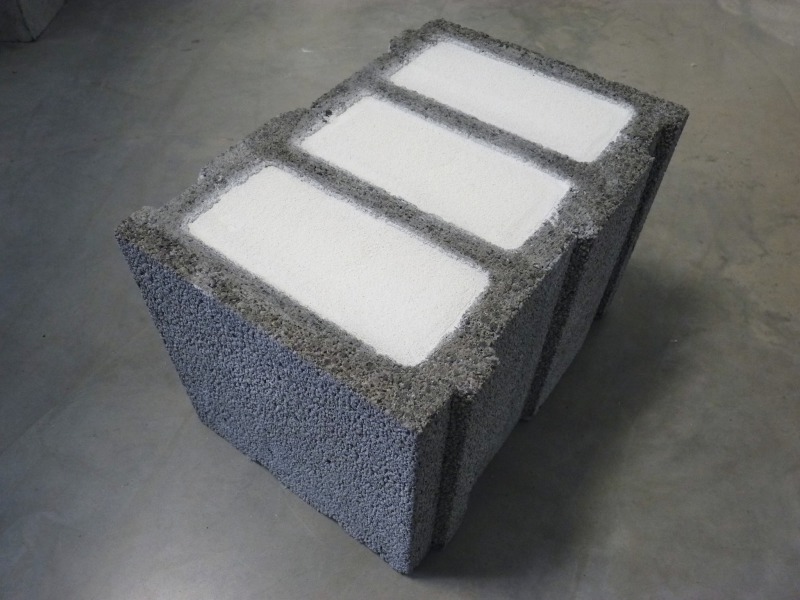

Insulating Concrete Forms, (ICF's) are used to construct concrete based buildings. The molded foam blocks replace traditional forms and, since they remain in place after the pour, they provide excellent insulation and sound dampening qualities.

Foam Insulation Concrete Block Foam Insulation TipsFoam Insulation Tips

The concrete mixing plant mixes a slurry of cement or fly ash, sand, and water with a synthetic aerated foam to create foamed concrete. A foaming agent is used to generate stable air bubbles that resist physical and chemical processes during mixing, placing, and hardening. Foamed concrete can be poured or pumped into molds or structural elements.

Structural Insulated Panels (SIPs) and Insulated Concrete Forms (ICFs) Framing and insulation

Insulated concrete forms use expanded polystyrene foam panels reinforced with steel cables and rebar and filled with concrete, which makes a house extremely strong. Thus, ICF construction offers an easy way to attain hurricane-resistant wall systems that shield against flying debris, flooding, and wind.

Concrete is being poured into the wall forms made by the rigid foam insulated concrete form

Witness the incredible process of transforming a mixture of cement, water, and foam into lightweight and durable blocks that are revolutionizing the construction industry. From the pr.more.

New Product Foam Concrete Blocks Amarna Consult Ltd.

Amvic™ Insulated Concrete Forms (ICF) are a stay in place, 5-in-1 concrete forming system incorporating structure, insulation, an air/vapor barrier and a finish attachment. It is a cost effective, resilient and environmentally friendly construction system.

Foam concrete manufacturing Foam concrete machines

Quiet & Comfortable Green Construction and Sustainability ICF Disaster Resilience High Winds Fire Resistant Earthquake Resistant Tornado & Hurricane ICF Safe Rooms ICFs for Home Buyers ICFs for Contractors & Installers ICF vs CMU How to Use ICFs ICF Energy Efficiency Energy Savings BUILDBLOCK ICFs Overview Find A Distributor ICF Training

Rectangular Foam Concrete Block, Size 625 x 250 x 115 mm, Rs 2250 /cubic meter ID 17313359212

1 Prepare the materials. Download Article Ensure that you have all the correct materials. The needed supplies include sand, water, block molds, gloves, and safety glasses. Do not worry if you do not have a cement mixer, as it can be substituted by a wheelbarrow. 2 Calculate the amount of materials you'll need. Download Article

Amazing Concept Concrete Form House, House Plan App

Foam concrete is a lightweight concrete that is made with dense foam, or suds added to a concrete slurry mix (cement and water). The dense foam is the aggregate in this mixture instead.

Foam concrete blocks YouTube

Foam concrete is in the form of foamed grout or foamed mortar. Foam concrete can be defined as a cementitious material that consists of minimum 20 percent of foam, that is mechanically entrained into the plastic mortar. The dry density of foamed concrete may vary from 300 to 1600 kg/m3.

Foam concrete blocks sizes, weight, characteristics, properties Foam concrete machines

Method #2: Spray Foam for Insulating Concrete Block Walls. The alternative method involves constructing an additional wall on the interior, creating a cavity that can be filled with insulation. This approach opens up numerous possibilities, including using foam boards or a combination of materials. For optimal insulation performance, spray foam.

Rectangle Foam Concrete Block, Size (Inches) 24 X 8 X 4 Inch at Rs 3100/cubic meter in Belgaum

From pouring a concrete pad and laying concrete blocks for retaining walls to repairing a brick wall, you can find all the materials and accessories to make your job a success. We carry ready-mix concrete, standard concrete mix, cement mix, stucco mix and other masonry mixes for tasks like post setting and concrete repair .